Heat Shrinkable Moulded Shapes

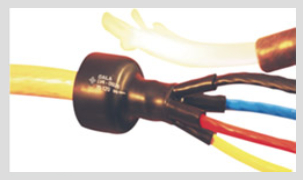

Heat Shrink Low Voltage Cable Breakout

Insulcore-Low voltage provides a strong and permanent environmental seal to the crutch of 2, 3, 4, 5, 6 and 7 core PVC, XLPE Rubber and PILC cables upto 3.3 KV rated voltage.

The Breakouts are Manufactured form high quality cross linked polyolefin material that offer an exceptional insulation and long term service reliability.

The Breakouts are internally coated with hot melt adhesive. These breakouts when installed in position provide 100% water/moisture proofness to the system according to IP 68 (Ingress Protection).

Customised dimensions of Breakouts available on request. Special Flame Retardant Breakouts can be provided on demand.

Technical Qualification Report No.: QR 1012

Meets IP 68 (ingress Protection)

SELECTION CHART

All dimensions are in mm

| Code | No. of Core | D | d | L | I | Tb | Tc | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Ds | Df | ds | df | Ls | Lf | ls | lf | f | f | ||

| min. | max. | min. | max. | min. | max. | min. | min. | ±10% | ±10% | ||

| LV2GBB-0308 S | 2 | 22 | 8 | 9 | 3 | 70 | 85 | 14 | 20 | 2.2 | 2.0 |

| LV2GBB-0308 | 2 | 28 | 8 | 12 | 3 | 70 | 85 | 15 | 20 | 2.2 | 2.0 |

| LV2GBB-0410 | 2 | 32 | 10 | 14 | 4 | 67 | 85 | 15 | 20 | 2.2 | 2.0 |

| LV2GBB-0410 A | 2 | 42 | 11 | 14 | 4 | 80 | 107 | 25 | 42 | 2.2 | 2.0 |

| LV2GBB-0410 L | 2 | 34 | 10 | 14 | 4 | 77 | 107 | 27 | 42 | 3.0 | 3.0 |

| LV2GBB0610 | 2 | 30 | 10 | 19 | 6 | 110 | 145 | 50 | 60 | 2.0 | 2.0 |

| LV2GBB-0610L* | 2 | 30 | 8 | 19 | 6 | 135 | 165 | 50 | 60 | 2.5 | 2.0 |

| LV2GBB-0615 | 2 | 45 | 15 | 18 | 5.5 | 90 | 110 | 25 | 43 | 3.0 | 3.5 |

| LV2GBB-0720 | 2 | 60 | 20 | 24 | 7 | 95 | 120 | 25 | 34 | 3.0 | 2.5 |

| LV2GBB-0720 A | 2 | 70 | 22 | 30 | 8 | 90 | 120 | 25 | 34 | 3.0 | 2.5 |

| LV2GBB-0830* | 2 | 65 | 30 | 25 | 8 | 120 | 150 | 50 | 60 | 2.0 | 1.8 |

| LV2GBB-0930* | 2 | 70 | 30 | 27 | 8 | 120 | 150 | 50 | 65 | 3.0 | 3.0 |

| LV2GBB-1565* | 2 | 125 | 65 | 46 | 15 | 110 | 130 | 40 | 55 | 2.5 | 2.2 |

| LV2GBB-1565 A* | 2 | 150 | 65 | 50 | 15 | 105 | 130 | 40 | 55 | 2.5 | 2.2 |

| LV2GBB-2075* | 2 | 175 | 70 | 40 | 20 | 150 | 210 | 60 | 80 | 2.5 | 2.2 |

| LV2GBB-2075 A* | 2 | 200 | 70 | 55 | 20 | 155 | 210 | 62 | 80 | 2.5 | 2.2 |

| LV2GBB-24135* | 2 | 240 | 135 | 65 | 24 | 190 | 245 | 60 | 104 | 2.3 | 2.0 |

| LV2GBB-55175* | 2 | 255 | 175 | 86 | 55 | 160 | 200 | 50 | 80 | 2.8 | 2.5 |

| LV2GBB-55175 A* | 2 | 370 | 175 | 156 | 55 | 150 | 200 | 50 | 80 | 2.8 | 2.5 |

| LV3GBB-0308* | 3 | 32 | 8 | 12 | 2.8 | 90 | 104 | 20 | 28 | 2.2 | 1.8 |

| LV3GBB-0309 | 3 | 32 | 9 | 12 | 3 | 85 | 100 | 15 | 24 | 2.0 | 1.7 |

| LV3GBB-0413 | 3 | 36 | 14 | 15 | 4 | 80 | 100 | 15 | 21 | 2.2 | 2.0 |

| LV3GBB-0413 A | 3 | 45 | 14 | 15 | 4 | 80 | 100 | 15 | 21 | 2.2 | 2.0 |

| LV3GBB-0820 | 3 | 60 | 20 | 25 | 8 | 160 | 184 | 45 | 60 | 3.3 | 2.7 |

| LV3GBB-0820 A | 3 | 70 | 20 | 27 | 8 | 155 | 184 | 40 | 60 | 3.3 | 2.7 |

| LV3GBB-1330 | 3 | 80 | 30 | 36 | 13 | 185 | 215 | 60 | 75 | 3.6 | 3.3 |

| LV3GBB-1330 A | 3 | 100 | 30 | 39 | 13 | 185 | 215 | 60 | 75 | 3.6 | 3.3 |

| LV3GBB-2145 | 3 | 110 | 45 | 55 | 21 | 200 | 235 | 70 | 88 | 3.5 | 2.9 |

| LV3GBB-2145 A | 3 | 125 | 45 | 57 | 21 | 190 | 230 | 65 | 88 | 3.5 | 2.9 |

| LV3GBB-1760 | 3 | 119 | 60 | 45 | 17 | 140 | 185 | 60 | 85 | 4.5 | 4.5 |

| LV3GBB-1760 A | 3 | 150 | 60 | 57 | 17 | 130 | 185 | 55 | 85 | 4.5 | 4.5 |

| LV3GBB-2755 | 3 | 140 | 56 | 68 | 28 | 215 | 260 | 75 | 90 | 3.5 | 3.5 |

| LV3GBB-2755 A | 3 | 180 | 58 | 68 | 29 | 200 | 260 | 70 | 90 | 3.5 | 3.5 |

| LV3GBB-3060 | 3 | 200 | 60 | 70 | 30 | 190 | 250 | 70 | 85 | 4.0 | 3.0 |

| LV4GBB-0209* | 4 | 28 | 9 | 9 | 2.5 | 90 | 115 | 15 | 20 | 2.2 | 1.7 |

| LV4GBB-0309 | 4 | 28 | 9 | 9 | 2.6 | 64 | 75 | 22 | 28 | 2.4 | 2.1 |

| LV4GBB-0312S | 4 | 30 | 12 | 10 | 3 | 80 | 100 | 15 | 25 | 2.4 | 1.7 |

| LV4GBB-0312 | 4 | 40 | 12 | 12 | 3 | 78 | 100 | 15 | 25 | 2.4 | 1.7 |

| LV4GBB-0415 | 4 | 41 | 16 | 14 | 4 | 75 | 100 | 15 | 23 | 2.4 | 1.7 |

| LV4GBB-0415 A | 4 | 50 | 17 | 17 | 4 | 75 | 95 | 12 | 23 | 2.4 | 1.7 |

| LV4GBB-0522 | 4 | 50 | 22 | 18 | 5 | 95 | 115 | 30 | 37 | 2.5 | 2.2 |

| LV4GBB-0821 | 4 | 57 | 26 | 20 | 7 | 140 | 170 | 32 | 48 | 3.5 | 2.5 |

| LV4GBB-0825 N | 4 | 68 | 25 | 25 | 8 | 155 | 188 | 35 | 48 | 3.5 | 2.3 |

| LV4GBB-0925 | 4 | 70 | 30 | 25 | 9 | 155 | 190 | 35 | 48 | 3.7 | 2.6 |

| LV4GBB-1130 | 4 | 80 | 31 | 32 | 10 | 150 | 190 | 28 | 47 | 3.7 | 2.6 |

| LV4GBB-1130L* | 4 | 80 | 30 | 35 | 11 | 180 | 210 | 35 | 52 | 3.7 | 2.6 |

| LV4GBB-1334 | 4 | 90 | 42 | 35 | 13 | 170 | 210 | 35 | 52 | 3.7 | 2.6 |

| LV4GBB-1334 A | 4 | 110 | 44 | 35 | 13 | 170 | 208 | 40 | 51 | 3.7 | 2.6 |

| LV4GBB-2454 | 4 | 125 | 44 | 40 | 14 | 170 | 208 | 30 | 51 | 3.7 | 2.6 |

| LV4GBB-2880* | 4 | 180 | 80 | 70 | 28 | 215 | 260 | 75 | 90 | 2.5 | 2.5 |

| LV4GBB-4080 | 4 | 180 | 80 | 70 | 40 | 200 | 260 | 75 | 95 | 3.7 | 2.8 |

| LV4GBB-1880* | 4 | 215 | 80 | 50 | 18 | 150 | 175 | 30 | 45 | 2.5 | 2.5 |

| LV4GBB-1880 SA | 4 | 180 | 80 | 63 | 18 | 150 | 175 | 35 | 45 | 2.5 | 2.5 |

| LV4GBB-1880 S | 4 | 180 | 80 | 50 | 18 | 155 | 175 | 35 | 45 | 2.5 | 2.5 |

| LV5GBB-0308 | 5 | 32 | 8 | 10 | 3 | 95 | 115 | 22 | 28 | 2.1 | 1.7 |

| LV5GBB-0311 | 5 | 32 | 11 | 10 | 3 | 55 | 75 | 15 | 20 | 2.3 | 2.0 |

| LV5GBB-0415 | 5 | 50 | 16 | 15 | 4 | 85 | 110 | 21 | 33 | 3.2 | 2.6 |

| LV5GBB-0415 A | 5 | 57 | 17 | 15 | 4 | 80 | 110 | 21 | 33 | 3.2 | 2.6 |

| LV5GBB-0524* | 5 | 55 | 24 | 18 | 5 | 145 | 155 | 40 | 45 | 3.3 | 2.6 |

| LV5GBB-0832 | 5 | 80 | 32 | 26 | 8 | 155 | 190 | 55 | 65 | 3.3 | 2.8 |

| LV5GBB-0832 A | 6 | 85 | 37 | 25 | 7 | 100 | 140 | 30 | 45 | 3.2 | 2.6 |

| LV6GBB-0412 | 6 | 44 | 12 | 13 | 4 | 55 | 82 | 20 | 30 | 2.2 | 2.0 |

| LV6GBB-0737 | 6 | 85 | 37 | 25 | 7 | 100 | 138 | 30 | 46 | 3.2 | 2.6 |

| LV7GBB-0737 | 7 | 95 | 37 | 26 | 7 | 100 | 135 | 40 | 55 | 2.7 | 2.6 |

| LV7GBB-1845 | 7 | 118 | 46 | 35 | 19 | 110 | 145 | 32 | 52 | 4.3 | 3.0 |

D,d : Internal Diameter ; s : as supplied ; f : after free recovery ; Tb,Tc : Thickness of body & core ** New Designs

| Code | No. of Core | Ds | d1 | d2 | L | l1 | l2 | Tb | Tc | Tc1 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ds | Df | ds | df | ds | df | Ls | Lf | ls | lf | ls | lf | f | f | f | ||

| min | max | min | max | min | max | min | min | min | min | min | min | ±10% | ±10% | ±10% | ||

| LV2GBB-61820 | 2 | 65 | 20 | 44 | 18 | 25 | 6 | 105 | 124 | 28 | 40 | 28 | 40 | 4.0 | 3.1 | 3.0 |

| LV5GBB-5725 | 5 | 65 | 25 | 23 | 7 | 16 | 5 | 125 | 150 | 40 | 51 | 35 | 40 | 2.5 | 2.5 | 2.0 |

| LV5GBB-7939 | 5 | 90 | 39 | 30 | 9 | 24 | 7 | 133 | 185 | 30 | 50 | 30 | 50 | 2.7 | 2.7 | 2.7 |

| LV5GBB-7939 A | 5 | 100 | 39 | 35 | 9 | 16 | 7 | 133 | 185 | 30 | 50 | 30 | 50 | 2.7 | 2.7 | 2.7 |

TECHNICAL SPECIFICATION

- PROPERTIES

- VALUE

- STANDARD

- Physical

- Tensile Strength

- 12 N/mm2 (MPA)(min.)

- ASTM D638

- Ultimate Elongation

- 350% (Min.)

- ASTM D638

- Density

- 1.05 ± 0.2 gm/cm3

- ASTM D792

- Hardness

- 45 ± 10 Shore D

- ASTM D2240

- Water Absorption

- 0.2 % (max.)

- ASTM D570

- Thermal

- Accelerated Ageing

- (120oC for 500 Hrs)

- ASTM D2671

- Tensile Strength

- 11 N/mm2 (Mpa) (min.)

- ASTM D 638

- Ultimate Elongation

- 300%(Min.)

- ASTM D638

- Low temperature Flexibility (-40oC for 4 Hrs.)

- No Cracking

- ASTM D2671

- Heat Shock (250oC for 30 Min.)

- No Cracking or flowing

- ESI 09-11

- Shrink Temperature

- 125oC

- IEC 216

- Continuous Temperature limit

- -40oC to + 110oC

- IEC 216

- Electrical

- Dielectric Strength

- 12 KV/mm. (Min.)

- ASTM D149

- Volume Resistivity

- 1 x 1014 Ohm.cm(min.)

- ASTM D257

- Dielectric Constant

- 5 (Max.)

- ASTM D150

Products

Heat Shrinkable Moulded Shapes

Heat Shrink Tubes / Heat Shrink Sleeves

- Advantages Of Heat shrink Tubing

- Thin Wall Tubes

- GDW : Dual Wall Tubing

- Medium/Heavy Wall Tubes-Commercial

- Heat Shrink Co-extruded Tubing Premium Quality

- Red Insulation Tubes

- Non Tracking Tubes

- Busbar Sleeves

- Stress Control Tube

- Integrated Stress Control Tube-GVOT Tube

- Heat Shrink Double Layer Tube-GDTL Tube

- High Shrink Ratio Heat Shrink Tube

Switchgear Insulation Products

- Barrier Board Sheet

- End Sealing Kit for Extensible RMU/GIS Bushing

- Heat Shrink Bus Bar Sleeve

- Bus Bar Insulating Shrouds

- Bus Bar Insulating Shrouds Polyolefin

- Bus Bar End Caps

- Thin wall tube wire marking

- Heat Shrink Tape (Bustape)

- Insulation for Circuit Breakers

- Busbar Sleeve for 66 kV

- Bushing Boot

- Non Shrinkable High Voltage Tape

- Heat Shrinkable Gland