Heat Shrinkable Tubes/Heat Shrink Sleeves

Medium / Heavy Wall Tubes - Insultube Commercial

Insultube is Heat shrink Medium & Heavy wall tubing.

Medium wall tubes (GMW) are used for environmental protection of low voltage cable

termination and insulating the connectors for low

voltage straight through joints / splice rated upto 3.3kV. Heavy wall

tubes (GHW) are used for mechanical protection and outer sealing of

underground straight through cable joints / splice upto 36kV.

These tubes are manufactured from high quality cross inked

polyolefin material.

- Optional hot melt adhesive for complete environmental protection and insulation, according to IP 68 (Ingress Protection.)

- Conforms to IEC 60684-3-247 standard.

- Halogen Free.

- Excellent resistance to weathering, UV rays, chemical and solvents.

- Custom dimensions, thickness, length & colours available on request.

- Maximum cut length available - 1200 mm. for GMW / GHW series.

Technical Qualification Report : QR 1013

SELECTION CHART

All dimensions are in mm

- Code

- D Min. (mm)

- d Max. (mm)

- T±10% (mm)

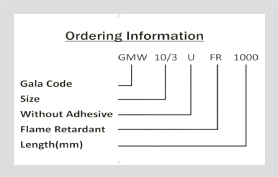

- GMW 10/3

- 10

- 3

- 1.5

- GMW 12/4

- 12

- 4

- 1.8

- GMW 16/5*

- 16

- 5

- 2.0

- GMW 19/6

- 19

- 6

- 2.0

- GMW 22/6

- 22

- 6

- 2.3

- GMW 25/8

- 25

- 8

- 2.5

- GMW 30/8

- 30

- 8

- 2.6

- GMW 33/10*

- 33

- 10

- 2.6

- GMW 40/12

- 40

- 12

- 2.7

- GMW 50/16

- 50

- 16

- 2.7

- GMW 65/19*

- 65

- 19

- 2.7

- GMW 70/22*

- 70

- 22

- 2.7

- GMW 75/22

- 75

- 22

- 2.7

- GMW 95/25*

- 95

- 25

- 3.0

- GMW 105/30

- 105

- 30

- 3.0

- GMW 115/34

- 115

- 34

- 3.2

- GMW 130/36

- 130

- 36

- 3.2

- GMW 130/36

- 130

- 36

- 3.2

- GMW 140/42

- 140

- 42

- 3.2

- GMW 160/50

- 160

- 50

- 3.3

- GMW 180/55

- 180

- 60

- 3.3

- GMW 200/60

- 200

- 60

- 3.5

- GMW 250/70

- 250

- 70

- 3.5

- GMW 320/90

- 320

- 90

- 3.5

- GMW 375/110

- 375

- 110

- 3.5

- Code

- D Min. (mm)

- d Max. (mm)

- T±10% (mm)

- GHW 12/3

- 12

- 3

- 2.4

- GHW 19/6

- 19

- 6

- 2.5

- GHW 22/6

- 22

- 6

- 2.7

- GHW 25/8

- 25

- 8

- 2.8

- GHW 30/8

- 30

- 8

- 3.0

- GHW 33/10*

- 33

- 10

- 3.0

- GHW 40/12

- 40

- 12

- 4.0

- GHW 50/16*

- 50

- 16

- 4.0

- GHW 65/19*

- 65

- 19

- 4.0

- GHW 70/22*

- 70

- 22

- 4.0

- GHW 75/22

- 75

- 22

- 4.0

- GHW 95/25*

- 95

- 25

- 4.0

- GHW 105/30

- 105

- 30

- 4.0

- GHW 115/34*

- 115

- 34

- 4.0

- GHW 130/36*

- 130

- 36

- 4.0

- GHW 140/42

- 140

- 42

- 4.2

- GHW 160/50

- 160

- 50

- 4.3

- GHW 180/55

- 180

- 55

- 4.3

- GHW 200/60

- 200

- 60

- 4.3

- GHW 250/70

- 250

- 70

- 4.3

- GHW 320/90

- 320

- 90

- 4.5

- GHW 375/110

- 375

- 110

- 4.5

- GHW 425/120

- 425

- 120

- 4.5

TECHNICAL SPECIFICATION

| Properties | Value | Standard |

|---|---|---|

| Physical | ||

| Tensile Strength | 12 N/mm2 (MPA)(min.) | ASTM D638 |

| Ultimate Elongation | 350% (Min.) | ASTM D638 |

| Longitudinal Change | -10% (Max.) | ASTM D2671 |

| Density | 1.0 ± 0.2 gm/cm3 | ASTM D792 |

| Hardness | 45 ± 10 Shore D | ASTM D2240 |

| Water Absorption | 0.5 % (max.) | ASTM D570 |

| Thermal | ||

| Accelerated Ageing | (150oC for 168 hrs.) | ASTM D2671 |

| Tensile Strength | 12 N/mm2 (Mpa) (min.) | ASTM D 638 |

| Low temperature Flexibility (-40oC for 4 Hrs.) | No Cracking | ASTM D2671 |

| Heat Shock (250oC for 30 Min.) | No Cracking or flowing | ESI 09-11 |

| Shrink Temperature | 125oC | IEC 216 |

| Continuous Temperature limit | -40oC to + 110oC | IEC 216 |

| Electrical | ||

| Dielectric Strength | 12 KV/mm. (Min.) | ASTM D149 |

| Volume Resistivity | 1 x 1012 Ohm.cm(min.) | ASTM D257 |

| Dielectric Constant | 5 (Max.) | ASTM D150 |

| Weathering: The material from which Medium and Heavy wall tubings are manufactured contains carbon black to protect it from UV light. | ||

Products

Heat Shrink Tubes / Heat Shrink Sleeves

- Advantages Of Heat shrink Tubing

- Thin Wall Tubes

- GDW : Dual Wall Tubing

- Medium/Heavy Wall Tubes-Commercial

- Heat Shrink Co-extruded Tubing Premium Quality

- Red Insulation Tubes

- Non Tracking Tubes

- Busbar Sleeves

- Stress Control Tube

- Integrated Stress Control Tube-GVOT Tube

- Heat Shrink Double Layer Tube-GDTL Tube

Switchgear Insulation Products

- Barrier Board Sheet

- End Sealing Kit for Extensible RMU/GIS Bushing

- Heat Shrink Bus Bar Sleeve

- Bus Bar Insulating Shrouds

- Bus Bar Insulating Shrouds Polyolefin

- Bus Bar End Caps

- Thin wall tube wire marking

- Heat Shrink Tape (Bustape)

- Insulation for Circuit Breakers

- Busbar Sleeve for 66 kV

- Bushing Boot

- Non Shrinkable High Voltage Tape

- Heat Shrinkable Gland